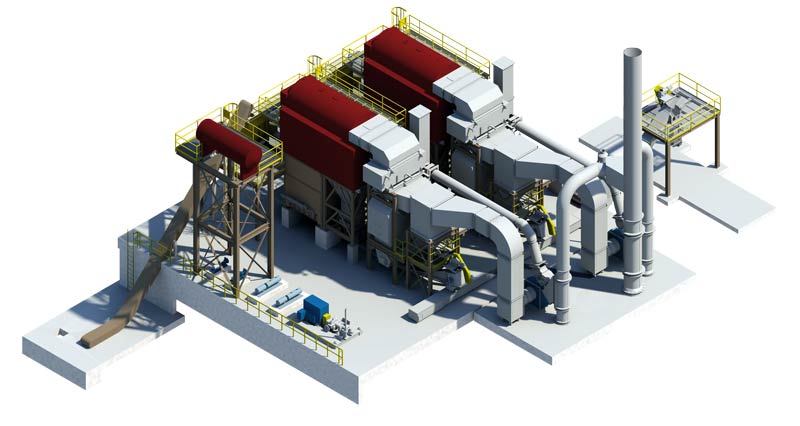

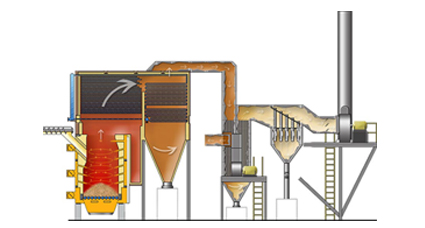

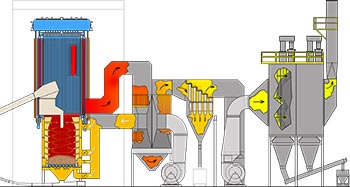

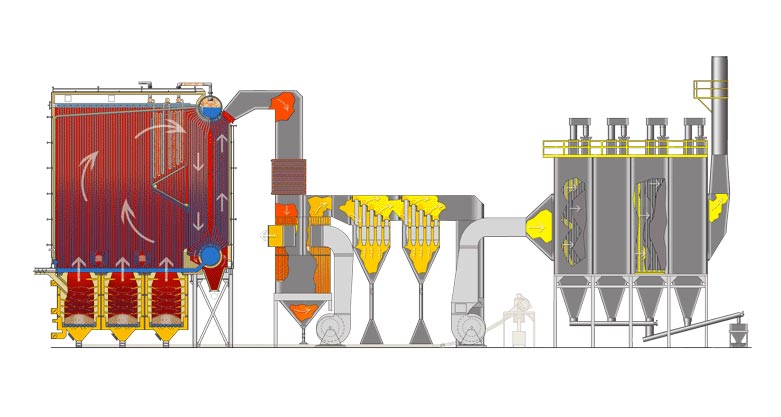

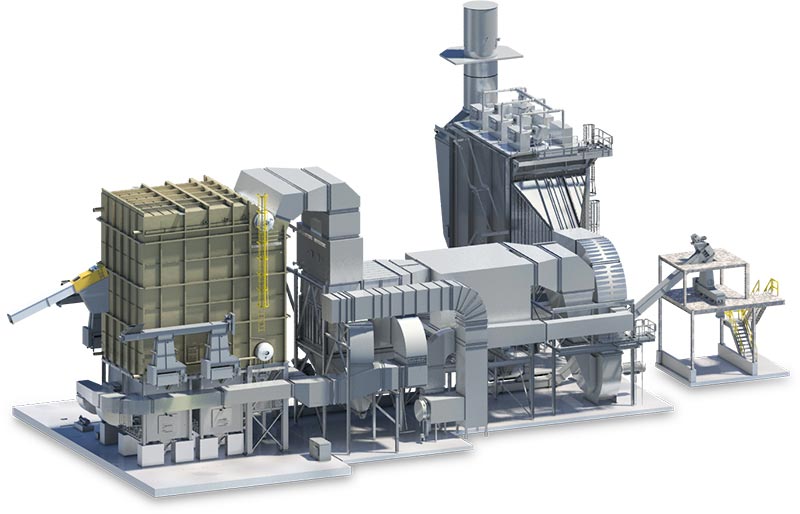

It's more important then ever to generate electrical power as inexpensively and efficiently as possible. One proven way to accomplish this is with a Wellons cogeneration system. Generating electricity and simultaneously satisfying plant process steam requirements is not a new idea, however the viability of such systems is more apparent than ever. Cogeneration from wood waste just makes good sense in today's energy conscious world.

Wellons, Inc. systems are known for their ability to burn virtually any combination of hogged wood, bark, sawdust, planer shavings, sanderdust and other wood fuels, with a broad range of moisture contents, without the need for supplemental fuel for either start-up or operation. Our reputation for high combustion efficiency, low emission rates, system reliability and service is based on more than 30 years of experience in the combustion of biomass fuels.